Excavations Shield and Shoring

Toolbox Safety Talk

Excavations

Excavations are recognized as one of the most hazardous operations in the construction industry. Excavation cave-ins can cause serious and often fatal injuries to employees. In addition to the hazards related to cave-ins, excavations are a concern on campus due to the University’s complex underground utility infrastructure. OSHA places very strict regulations governing the design of an excavation, cave-in prevention methods, and employee training. Cornell employees working in or around excavations need to be knowledgeable of safety requirements.

General Requirements for All Excavations

- All employees working in an excavation must receive initial training.

- A competent person must be clearly identified for all excavations. This person must be knowledgeable in assessing soil conditions, the use of protective systems, and OSHA requirements.

- Before beginning excavation, establish the locations of underground and overhead utilities and services.

- When applicable contact utility companies and advise them prior to the start of excavation

- Use Personal Protective Equipment:

- Wear hard hat, safety glasses, safety gloves, high-visibility vest and safety shoes

- Do not permit people underneath the loads of lifting or digging equipment.

- When hazardous atmospheric conditions exist or can reasonably expect them to exist, test and control the atmosphere to prevent exposure to harmful levels.

- Keep surcharge loads at least 2 feet from trench edges.

- Keep heavy equipment away from trench edges.

- Precautions must be taken to ensure vibrating equipment/vehicular traffic does not cause a cave-in.

- Employees working in trenches 4 feet deep or more should have an adequate and safe means of exit, such as ladders, steps or ramps available at no more than 25 feet of lateral travel.

- Do not work in excavations if there is accumulated water unless they follow necessary safety precautions.

- The Daily Trenching/Excavation Log must be completed, and a copy must remain on site.

- If conditions change in or around the excavation, employees must exit the excavation and a competent person must re-inspect and give approval for employees to re-enter.

Shoring and Shielding

Shoring and shielding are protecting systems used when the location or depth of the cut makes sloping back to the maximum allowable slope impractical. There are multiple types of shoring and shielding systems available and they can be used in all soil types

Shoring

Shoring is the provision of using a support system for trench faces which prevents movement of soil, underground utilities, roadways, and foundations. Each method has its own particular advantages and disadvantages, however hydraulic tends to be preferred because it is the safer option.

- Hydraulic shoring consists of using hydraulic pistons which are pumped outward till they press against the walls of the trench. It is a prefabricated strut and/or wale system manufactured of aluminum or steel and provides a critical safety advantage over timber shoring because workers do not have to enter the trench to install or remove hydraulic shoring.

- All shoring should be installed from the top down and removed from the bottom up

- Hydraulic shoring should be checked at least once per shift for leaking hoses and/or cylinders, broken connections, cracked nipples, bent bases, and any other damaged or defective parts

- Pneumatic shoring works in a manner similar to hydraulic shoring. The primary difference is that pneumatic shoring uses air pressure in place of hydraulic pressure.

- Screw jack systems differ from hydraulic and pneumatic systems in that the struts of a screw jack system must be adjusted manually. This system creates a hazard because the worker is required to be in the trench in order to adjust the strut.

- Single-Cylinder Hydraulic Shore are generally used in a water system, as an assist to timber shoring systems, and in shallow trenches where face stability is required.

- Underpinning has a process that involve stabilizing adjacent structures, foundations, and other intrusions that may have an impact on the excavation. This system should be conducted only under the direction and with the approval of a registered professional engineer.

Shielding

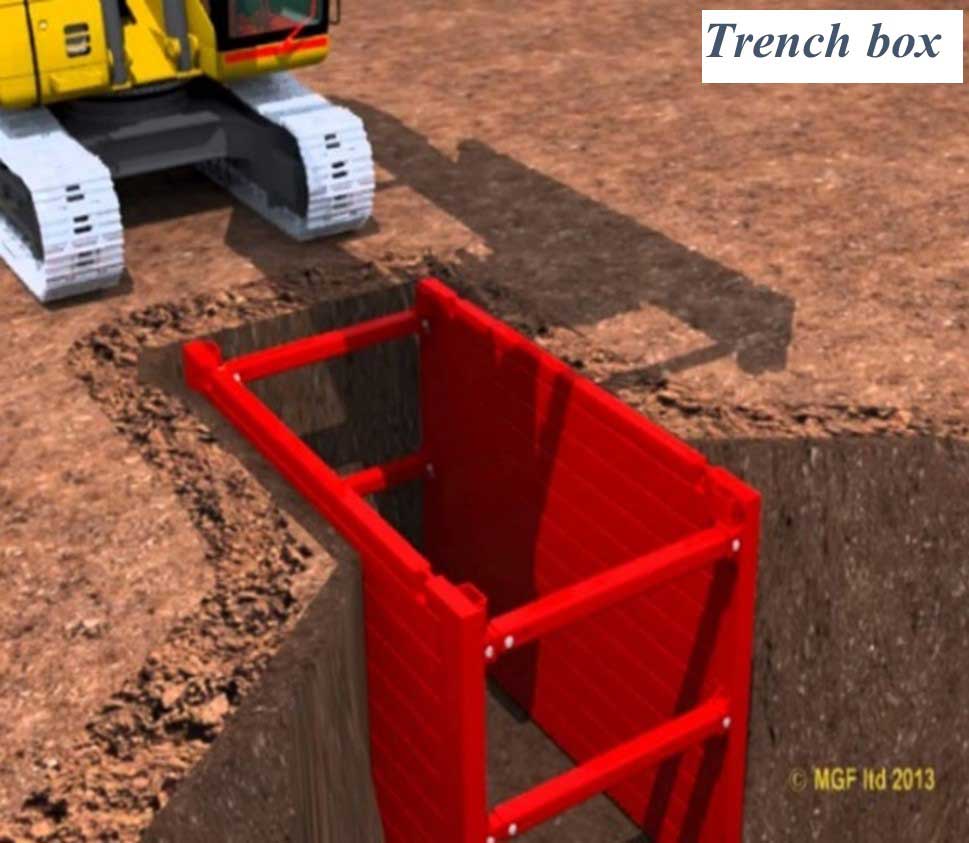

Shielding systems include trench boxes, steel plates, and/or combination of protective systems. Shielding does not protect against soil failures. Shielding systems do not support the face of excavations, rather they protect the workers inside of them. For that reason, shielding systems do not allow anyone to work outside the protection of the system being used. These systems must be used in accordance with manufacturer recommendations.

- Trench boxes - Trench boxes are intended primarily to protect workers from cave-ins and similar incidents.

- The excavated area between the outside of the trench box and the face of the trench should be as small as possible

- The space between the trench boxes and the excavation side are backfilled to prevent lateral movement of the box

- Shields may not be subjected to loads exceeding those which the system was designed to withstand

- The box must extend at least 18 inches above the surrounding area if there is sloping toward the excavation

- Workers must enter and leave the shield in a protected manner, such as by ladder or ramp

- Do NOT remain in the shield while it is being moved

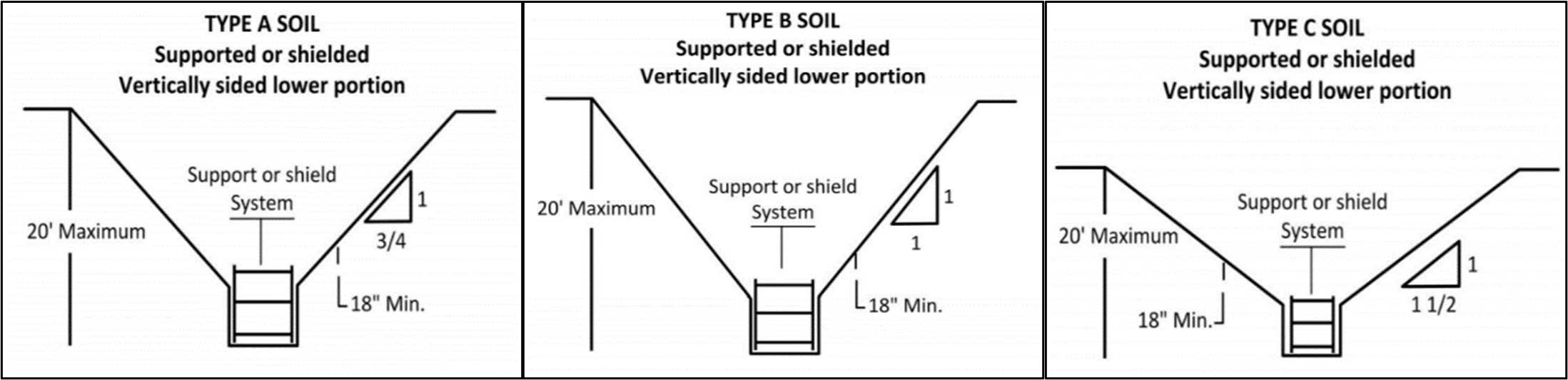

- Combined Use - Trench boxes are generally used in open areas, but they also may be used in combination with sloping and benching. The box should extend at least 18 inches above the surrounding area if there is sloping toward excavation. This can be accomplished by providing a benched area adjacent to the box. See the requirements in the figure and text below.

The requirements for excavations when using shielding (lower portion) in combination with sloping in Type A soil less than or equal to 20 feet deep (20' deep maximum). The maximum allowable slope for Type A soil is 1 to 0.75 (1' rise to 0.75' run).

The requirements for excavations when using shielding (lower portion) in combination with sloping in Type B soil less than or equal to 20 feet deep (20' deep maximum). The maximum allowable slope for Type B soil is 1 to 1 (1' rise to 1' run).

The requirements for excavations when using shielding (lower portion) in combination with sloping in Type C soil less than or equal to 20 feet deep (20' deep maximum). The maximum allowable slope for Type C soil is 1 to 1.5 (1' rise to 1.5' run).