Bench Grinder Safety Awareness Guide

Cornell Machine Shop Safety

Bench Grinder Safety Awareness Guide

Minimum Required PPE

-

Safety Glasses

-

Face Shield (only required if no eye shield guards present)

-

Hearing Protection

-

Closed-Toe Shoes

Hazards & Controls

- High-speed abrasive wheels with a large amount of energy can be a contact hazard. Do not touch the wheel.

- Improper installation of the wheel or a worn-out wheel can lead to malfunction, becoming an explosion hazard and flying object hazard. Visual inspections, proper training of installation, and ring testing can prevent this from happening.

- Rotating parts leave potential for entanglement hazards with loose clothing, hair, or jewelry. Do not wear loose clothing or jewelry in the shop. Tie long hair up and back.

- Workpieces being kicked back by rotating wheel create flying object hazards. All objects should be secure on the work rest when being ground.

- Rotating parts can create a pinch point or crushing hazard. Do not touch the wheel. Keep all guards in place and at the proper distances.

- The grinding wheel is hot after use, creating a burn, heat, or fire hazard. Do not touch the wheel after it has been used.

- The grinding wheel generates sparks, creating a fire hazard. Keep all combustibles away from sparks.

- There is a possibility of dust exposure that may create a health hazard. Know the hazards that may be created by the work material.

- Dust and material build-up can easily be a housekeeping issue. Always keep work areas clean from dust and other foreign materials.

Limitations

- Bench Grinders should not be used for softer materials such as (but not limited to) non-ferrous metals (brass, aluminum, copper), plastics, or wood.

- Materials smaller than 3 inches cannot be ground unless a proper fixture is used to keep hands far enough from coming in contact with the grinding wheel. The fixture must be able to hold the material being ground securely and without risk of becoming a projectile hazard.

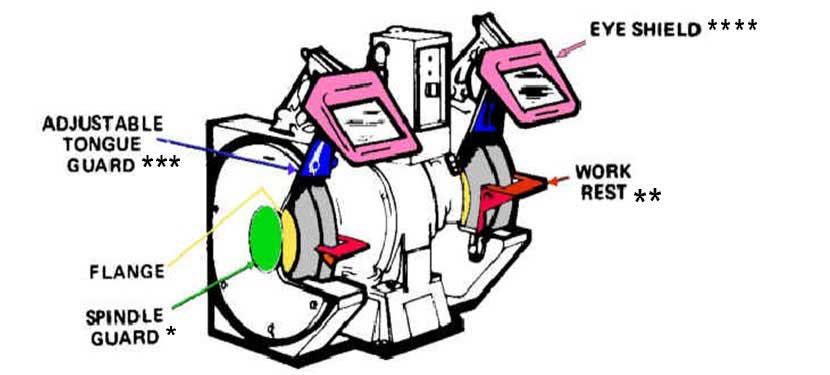

Machine Guarding

Note: All Machine Guards Must be in Place and/or Properly Adjusted Before Use.

Image courtesy of OSHA

* Side guards must cover the spindle, nut, and flange and 75% of the wheel diameter.

**The work rest must be kept adjusted to within 1/8-inch of the wheel.

***Adjustable tongue guards must be kept to within 1/4-inch of the wheel.

****If eye shields are not present, then the operator must don a face shield when grinding.

Other Precautions

- New grinding wheels should be installed and replaced by competent persons.

- The maximum RPM rating of the grinding wheel must be compatible with the RPM rating of the grinder motor.

- All grinding wheels should be visually inspected and ring tested before first use and periodically afterward.