Metalworking Lathe Safety Awareness Guide

Cornell Machine Shop Safety

Metalworking Lathe Safety Awareness Guide

Minimum Required PPE

- Safety Glasses

- Closed-toe Shoes

Hazards & Controls

-

Lathes contain several fast-rotating parts that can cause contact and entanglement hazards. Keep all body parts away from all rotating parts. Never wear loose-fitting clothing or jewelry while operating a lathe. Tie back and contain all long hair. Use guards to protect from accidental contact with rotating parts.

-

When the lathe spindle is set at too fast of an RPM, it will take longer for the spindle to stop rotating in an emergency situation. Limit spindle to 1000 RPM and use the lowest RPM applicable to the task.

-

Rotating and other moving parts can create pinch points. Pinch points can crush, bruise, lacerate, or amputate body parts. Utilize guards and avoid contact with these points.

-

Cutting Tools, drill bits, machined edges, chips, and cutoffs are potential cut and laceration hazards. Handle all sharp parts and tools with care. Do not clear chips with bare hands. Use a brush or compressed air (< 30psi).

-

There are several flying object hazards that can potentially come from a lathe. Make sure to secure both the workpiece and cutting tool. Be sure to remove the chuck key from the chuck. Make sure to keep the work area clean from all debris, chips, and tools.

-

High-speed metalworking can create burn hazards from the high amount of friction. Cutting chips, workpieces, and cutoffs can be hot to the touch during and immediately after the work process. Allow enough time for all objects to cool before handling them.

Limitations

- Machining of unusual or exotic materials can create new hazards depending on material composition. Only machine these materials under the supervision of a trained professional. Consult with the applicable Safety Data Sheets to learn more about specific material hazards.

Machine Guarding

| Chuck Guard | Workpiece Guard |

|---|---|

|

|

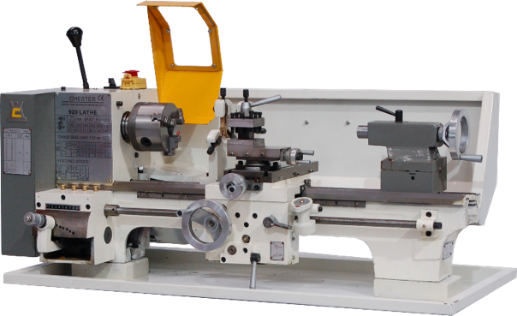

Image 1 - Chuck Guard: Protects user from accidental contact with the rotating chuck, helping to eliminate hazards such as pinch point, crushing, and entanglement.

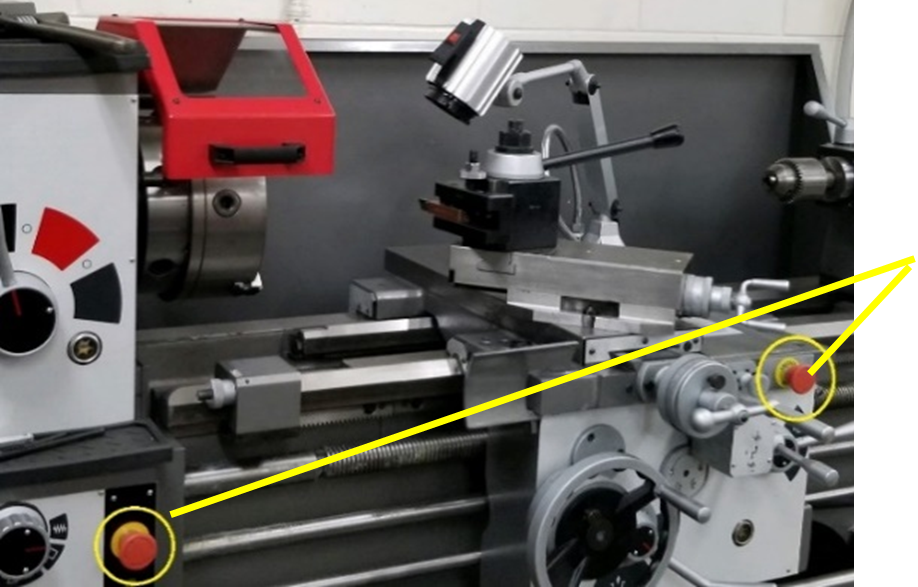

Image 2 - Workpiece Guard: Protects user from the rotating workpiece, helping to eliminate hazards such as crushing, pinch point, burning, and entanglement. This guard also protects users from flying projectiles and chips.

Other Precautions

Emergency Stop buttons should be located at easy to access locations on the machine. The purpose of these buttons is so the operator can stop the machine quickly in case of failure or an emergency situation such as becoming entangled in the machine. These buttons are typically located near the controls of operation.

- Never come near a rotating workpiece for reasons such as cleaning chips or measuring the workpiece. If you need to measure or clean the workpiece, stop the machine and wait for it to come to a full stop.

- If working on a heavy or awkward piece, use another person or some sort of lifting device to help lift and secure the workpiece.