Biological Safety Cabinets

A Biological Safety Cabinet (BSC) protects the researcher, the research materials, and other laboratory occupants through a controlled system of airflow and filtration. A BSC must be used when work involves infectious or potentially infectious biological materials and procedures that can generate aerosols, droplets, or splashes (e.g., vortexing, centrifuge loading or unloading, aliquoting, or open manipulation of cultures).

Engineering controls are a primary means of reducing exposure to biological hazards. Examples used in Cornell laboratories include general dilution ventilation, local exhaust ventilation, biological safety cabinets, glove boxes, safety shields, and appropriate storage facilities. The selection and use of these controls is informed by laboratory risk assessment and, where applicable, Institutional Biosafety Committee (IBC) review.

The OSHA Laboratory Standard requires that fume hoods and other protective equipment function properly and that specific measures are taken to ensure adequate performance. When work with human-derived materials presents splash or aerosol hazards, the OSHA Bloodborne Pathogens Standard requires engineering controls, for which a certified biosafety cabinet is typically the appropriate control. At Cornell, biosafety cabinets require certification to NSF/ANSI Standard 49 at least annually. Certification is performed by an external contractor under a university agreement.

Training

The Principal Investigator is responsible for ensuring laboratory personnel are trained in the proper use of biosafety cabinets. Training may be delivered through multiple methods and must be documented by the laboratory. Online training is available through Workday Learning and should be supplemented with task- and lab-specific instruction provided by the lab supervisor. Consistent training and expectations are foundational to safe and reliable cabinet use.

Operating in the BSC

Biosafety cabinets are not chemical fume hoods. They are designed to control biological aerosols and protect personnel, materials, and the environment—not to capture or exhaust chemical vapors.

Protect yourself and your work by wearing, at minimum, a fully buttoned lab coat and gloves while working in the BSC. Be consistent. Any time you leave the cabinet, remove gloves and decontaminate items before removal. Consistent behaviors—especially during routine work—are critical to maintaining containment.

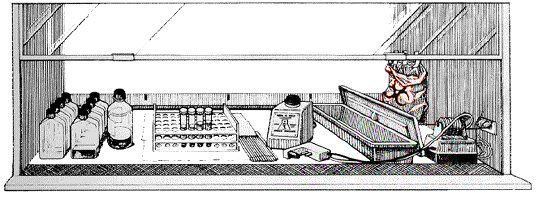

Plan work in advance and place only necessary materials inside the BSC, including appropriate waste containers (e.g., biohazard bags, sharps containers). Use slow, deliberate hand and arm movements, and enter and exit the cabinet in a straight (linear) path to minimize airflow disruption. Perform work at least 6 inches inside the cabinet and maintain a clean-to-dirty workflow.

Cabinet placement within the room matters. Foot traffic, doors, and supply air diffusers can create cross-drafts that compromise containment. Two people may work in a BSC only if the work is compatible and the cabinet is appropriately sized—typically an 8-foot cabinet.

If the cabinet alarm activates, stop work, secure materials if safe to do so, and contact EHS for evaluation.

Common causes of reduced BSC performance include overcrowding, blocked grilles, rapid movements, and poor cabinet placement. Attention to these basics supports both safety and experimental reliability.

Decontamination and Cleaning

Decontaminate the BSC before and after every use to prevent cross-contamination. A common method is a freshly prepared 1:10 bleach solution, followed by a 70% ethanol rinse to reduce corrosion and improve material compatibility. Contact EHS if a bleach alternative is needed. Your laboratory may have specific disinfectants identified through risk assessment.

Cleaning the rear and side surfaces of a BSC can be difficult. To avoid leaning into the cabinet or risking injury, use an extended tool (e.g., a Swiffer-style mop handle). Periodically clean and decontaminate the area beneath the work surface, where broken glass, spills, and debris can accumulate. Use tongs or forceps to remove broken glass. Establish a routine schedule for deeper cleaning (e.g., once or twice per year) and as needed.

Prior to service or removal of a biosafety cabinet, all materials must be removed and all interior surfaces disinfected by the laboratory.

Things to avoid when using a BSC

- Do not rely on UV light. UV is effective only on exposed surfaces. Dust accumulation and bulb aging significantly reduce effectiveness. UV does not replace chemical disinfection and is not considered a primary decontamination method.

- Do not spray corrosive disinfectants. Apply disinfectants using a squirt or drizzle bottle. Follow bleach with an ethanol rinse to minimize corrosion of internal components.

- Do not block the grilles or clutter the work surface. Obstructing the front or rear grilles disrupts airflow and compromises containment.

- Do not raise the sash. BSCs are designed to operate at a fixed sash height and should not be adjusted like chemical fume hoods.

- Do not use volatile or flammable chemicals. BSCs do not safely contain chemical vapors, which may be recirculated into the room and create inhalation or fire hazards.

- Do not use Bunsen burners. Open flames create fire hazards and airflow disruption. Safer alternatives include electric micro-incinerators (e.g., Bacti-Cinerator, Flame Boy). Contact EHS for guidance.

Procedure for Purchase of a Biosafety Cabinet

- Contact EHS Biosafety at askEHS@cornell.edu to discuss intent to purchase. Include the scope of work (biological materials and equipment) and the proposed location.

- EHS Biosafety will assess the proposed space for suitability. In general:

- Biosafety cabinets may not be installed beneath supply air diffusers.

- Biosafety cabinets may not be located directly opposite doors or major openings.

- Following the site assessment, the unit must be purchased through Cornell Procurement. Biosafety cabinets are not available through e-Shop.

Procedure for Certification of a Biosafety Cabinet

NSF/ANSI Standard 49 establishes minimum performance and testing requirements for Class II biosafety cabinets.

- A BSC in a BSL-1 or BSL-2 laboratory must be certified after installation, annually, and after relocation or service.

- A BSC in a BSL-3 laboratory must be certified after installation, at least annually, and after relocation or service. At Cornell, BSL-3 cabinets are certified every six months.

Integra Testing, a subsidiary of Steris Life Sciences, is the contracted certification provider for Cornell. Work is prohibited in biosafety cabinets that are uncertified or have expired certification.

Service may be requested directly through Integra Testing or by phone at 800-523-9852 ext. 43682. Certification services are not available through e-Shop.

Disposal of Biosafety Cabinets

Laboratories are responsible for coordinating proper disposal of biosafety cabinets. Laboratories manage decontamination and documentation; Facilities Management manages removal and disposal once clearance is confirmed.

- Contact EHS Biosafety at askEHS@cornell.edu to determine required decontamination.

- Surface decontaminate the cabinet.

- Request full cabinet and filter decontamination through Integra Testing.

- Ensure filters are removed and written confirmation of decontamination is provided.

- Post approved decontamination signage on the cabinet as outlined in Biological Decontamination of Laboratory Equipment.

Coordinate removal with Facilities Management at recycle@cornell.edu.

Updated January 21, 2026

Training Resources

Guidelines

Regulations

More Information

- Review Section 3.2 of the Biosafety Manual

- Attend “Working Safely in Biosafety Cabinets and Other Hoods” class – find it in Workday Learning as CVM 1074, "Working Safely in Biosafety Cabinets and other Hoods"

- Contact the Biosafety team at askEHS for tailored, hands-on BSC training in your lab or at our training lab, or for help finding an alternative to your Bunsen Burner. If you work at the College of Veterinary Medicine, you can also request this from Paul Jennette.

- Check out our related GBPs on aerosol-producing equipment, aspirator set up, and other items that might impact the way you use your BSC

- Check out our Cornell EHS YouTube channel that features biosafety cabinet videos - Cornell University Video - Techniques for Working Safely in a Biosafety Cabinet

- Biosafety Cabinet (BSC) is past due certification